Helping Get Your Mission Done

We are the workshop of mission driven companies:

Our engineering and design team consists of mechanical and aerospace engineers, with four to six years of education from an accredited university, who design things that have never been made before. With diverse skillsets and our experience in first design principles we promote intelligent constructive collaboration which allows us to follow through with designs from creation to development, and shipment.

Being registered under ITAR allows our CAD designs and collaboration to be compliant with their standards. Onshape, our CAD software, allows us to design anything we need from any tablet, including one’s phone. This allows easy accessibility to our designs.

Our designing and manufacturing processes are digitalized through Bridge, an innovative digital manufacturing software, allowing 100% traceability through every project.

Other Capabilities

Fusion Clean Energy Generation

We support nuclear fusion and fission research to produce carbon deficit energy.

Our teams create test equipment for super-conducting magnets, nuclear fuel handling, and Paschen-tight power transmission passthroughs. We specialize in high vacuum electrical passthroughs (from ambient air to cryogenic temperature in a vacuum environment) and study high pressure cryogenic environments with engineering teams that design critical nuclear components.

We create these to help replace dated energy generation with clean, sustainable, and abundant electricity.

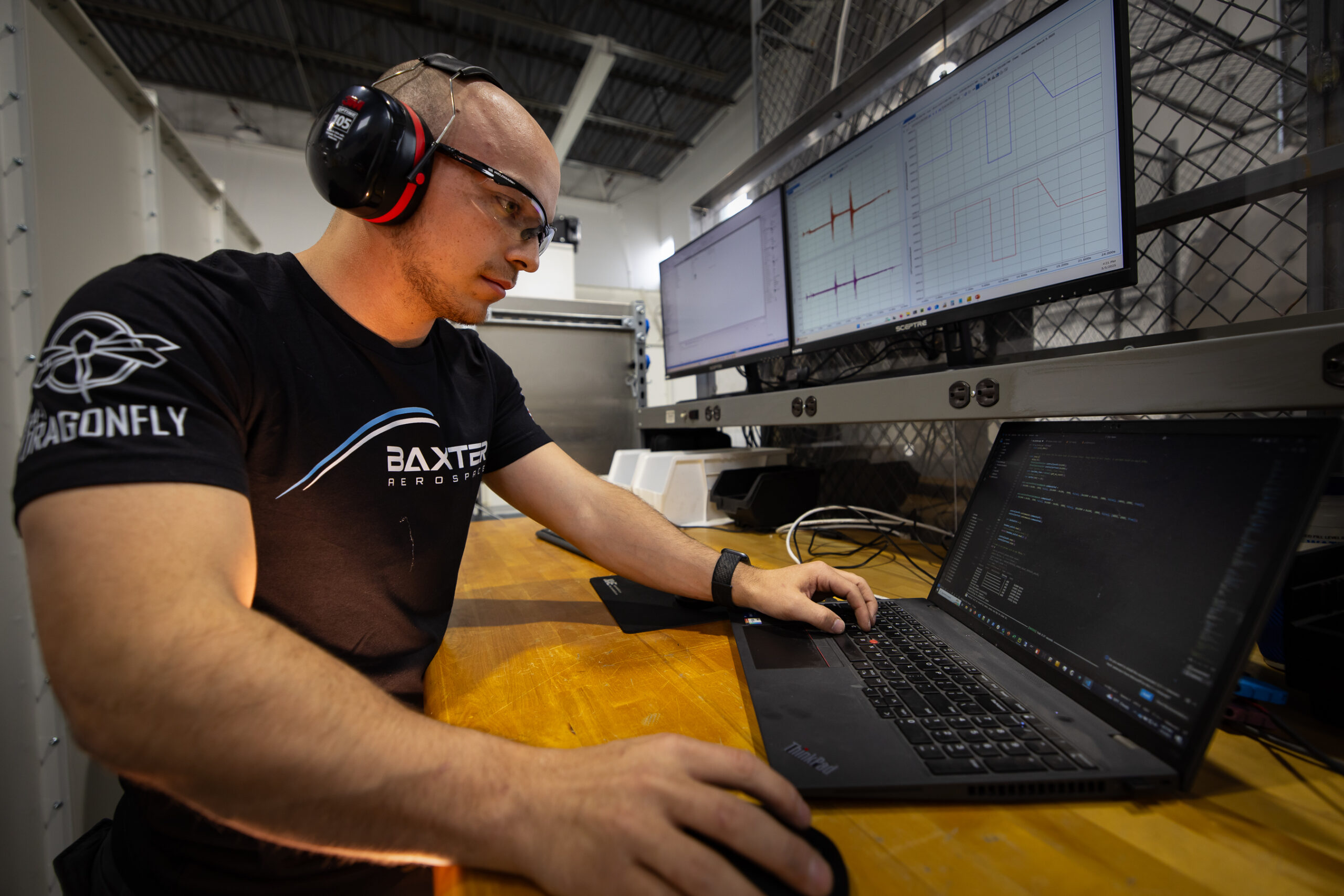

Spacecraft Manufacturing

We manufacture spacecraft componentry for mission drone companies. Our assembly teams construct hardware and fixtures for a variety of projects and build hardware for satellites and space flight testing.

Our wealth of knowledge for design and manufacturing allows us to give functional feedback and advice to our partners by supporting, prototyping, or building advanced space fight hardware.

We have contributed to ground support equipment where we built fire suppression systems, fuel pumps, high pressure cryogenic valve stations, and oxygen line cleaning machines for an engine test stand.

Baxter Aerospace Capabilities

of Experience

Spacecraft Manufacturing

We are the workshop for mission-driven companies—delivering precision aerospace engineering at scale.